Custom Solutions

Custom solutions based on Microtools

Through the Microtools platform and the various integrations already in place with the Microlise Fleet and Distribution platform, cost effective solutions may be developed that meet your business' specific requirements. Below are some examples of how we have worked with clients to rapidly deliver solutions.

DHL for the Homebase contract, plan their deliveries through Paragon based on estimated cage volumes. Whilst the number of cages are estimated from the received orders, when the actual orders are picked there may be a small discrepancy up or down.

Any variation between what the retail store is being asked to sign for, and the actual delivered cages is a cause for concern and leads to follow-up queries or the refusal to sign for the load.

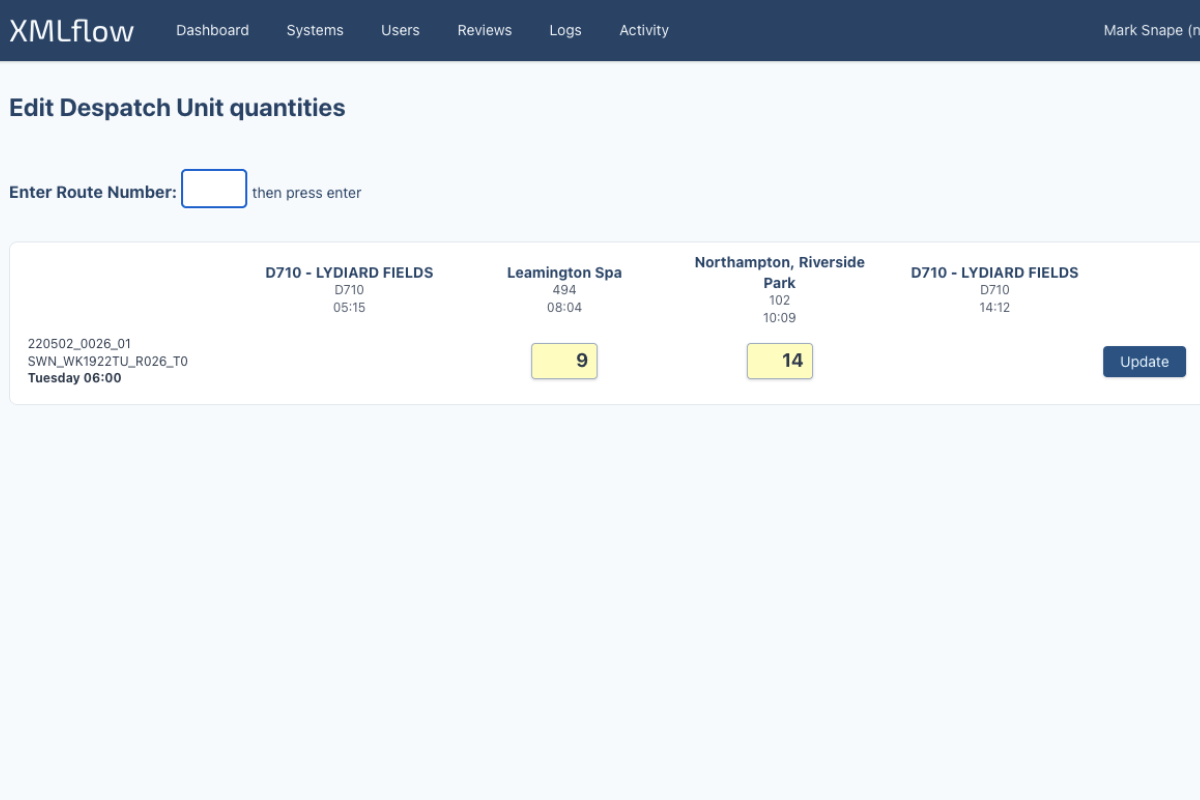

Microtools provided a solution that on closure of the trailer for a route at the depot, the transport staff are able to easily amend the delivery quantities to reflect quantities confirmed by the warehouse.

On entry of the route number, Microtools obtains the planned route from Microlise and presents it to the user. They can then adjust the volume and resubmit the journey to Microlise for execution.

Nisa Retail had a requirement to add an asset returns consignment into each and every delivery route.

Amending the export from their Paragon planning environments would be a costly and lengthy change as well as operational risk for an already implemented system

Novate through its Microtools platform was able to detect each time a new journey is passed to Microlise, then read the details back about that new journey, and create a Returns consignment from a simple template.

The solution operates completely automatically and was developed and delivered in less than two weeks.

Bestfood, a fulfillment service to high street food outlet chains needed a way to see how many dollies are being left at or brought back from each customer to ensure they have sufficient units to perform deliveries at peak periods.

At each delivery, the driver records the number of dollies 'In' and 'Out' of the customer via their SmartPod device.

Microtools checks the counts at each site departure ensuring that at the moment of the driver arriving at the depot, the expected number of dollies on the vehicle is evident to both transport and the driver.

The solution demonstrates to the drivers that the delivery assets are being managed and that they should comply with the company's desire to return as many as possible.

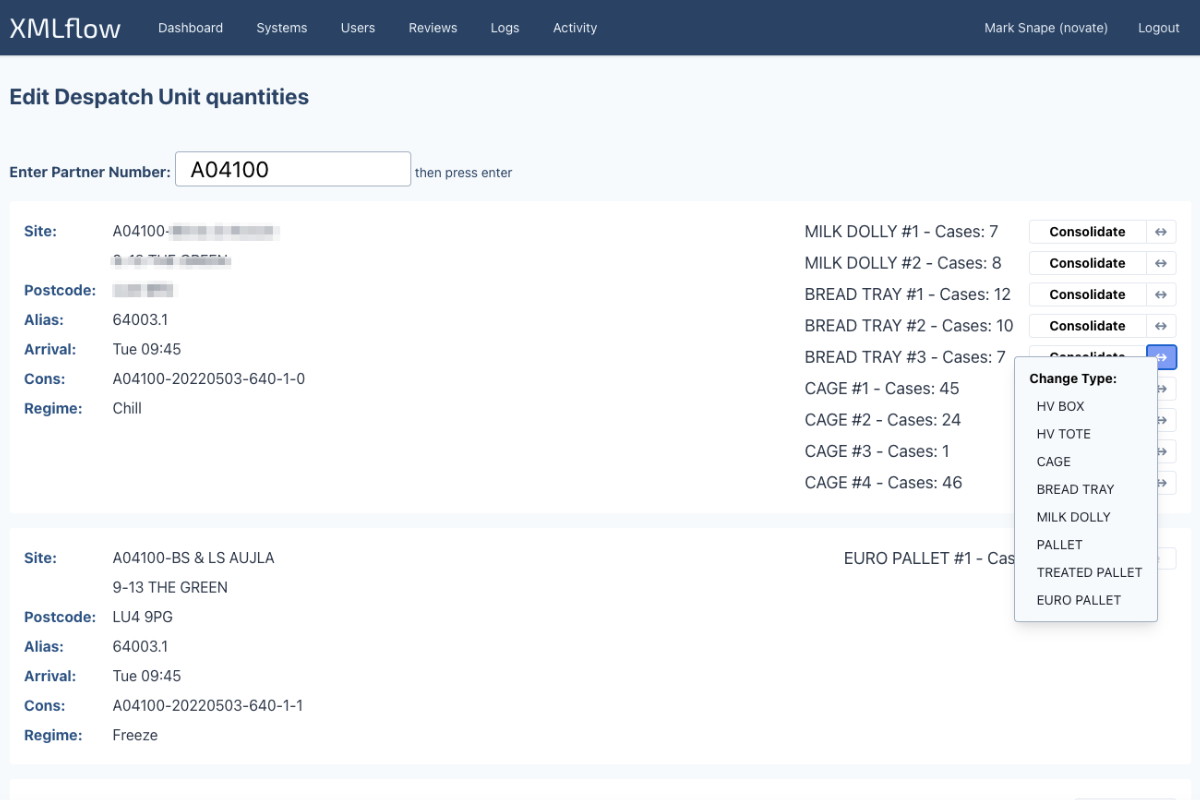

Nisa Retail operates a number of cross-dock operations, at which it may be necessary to consolidate cages that have been picked at different warehouses, or to change the media type for instance, moving a pallet of cases into a cage that is more appropriate for the partner receiving the delivery.

Via Microtools module XMLflow, users can enter a partner number and review up-coming delivery information. Users can consolidate items of the same time, or switch the media on any item.

The amended consignment is posted back into Microlise so that the delivery on the driver's SmartPod device is identical to the number and types of physical media present on the delivery, leading to less delivery enquiries for customer services.

A full audit trail is maintained of all changes, and a weekly report sent automatically to the business.

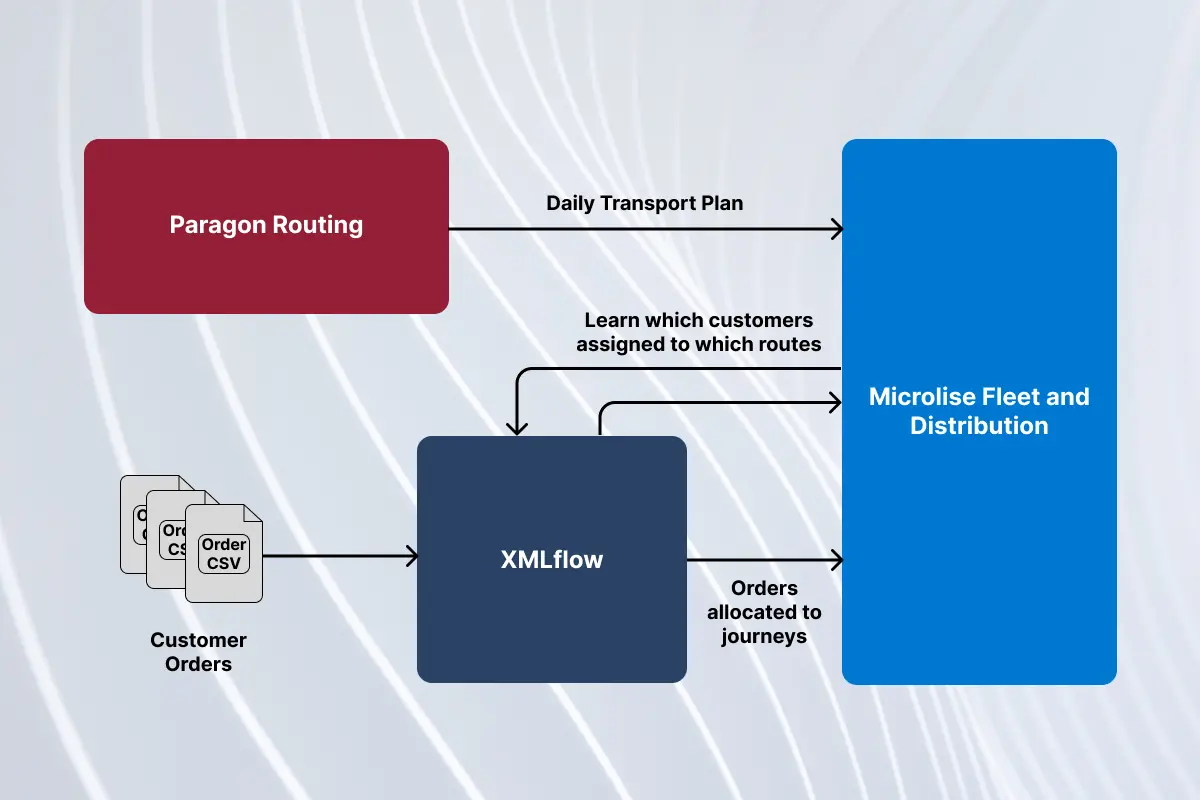

When Sharps Bedrooms full service logistics provider (LSP) pulled out of the UK, they made the decision to take transport back in house and implemented Paragon Routing to efficiently route each day's orders onto the most economical transport plan given the size of the fleet, the hours available, and customer commitments. The plan is then sent to Microlise so that the fleet can be monitored for transport and customer KPI.

Sharps also had Microlise SmartPOD for proof of delivery, but sending order details to Microlise was not part of the process implemented with Paragon. Since only Paragon knew which orders had been allocated to which vehicles, it was not easy for Sharps to send orders into Microlise and have them assigned to journeys.

Novate Microtools was able to help at short notice and implemented a solution that uses its XMLflow service to firstly listen to new journeys being created in Microlise and record the customer to unique route ID assignment. Then provide a facility for Sharps to upload CSV files of customer manifests into XMLflow through a simple web interface, for XMLflow to lookup the correct drop and then create Consignment Imports in Microlise that referenced the correct route and drop number for the order.

An initial solution was up and running in a couple of weeks, then with some fine tuning over a further couple of weeks.